Published on 27 August 2019

How to perform an automated & fast sample switch

Fast sample or medium switch – Real time video

Changing the injected liquid inside a microfluidic device has numerous applications, such as sequential sample injection for biochemistry and flow chemistry, or medium switch for cell biology and 3D cell culture on chip. The easiest solution is to replace the liquid injected, but it is often not possible.

In addition to introduce bubbles in the experiment, this solution doesn’t allow a fast switch. In this application note, we will describe how to perform an automated and fast medium switch thanks to the OB1 MK3+ pressure controller and a MUX Distributor.

LIST OF COMPONENTS

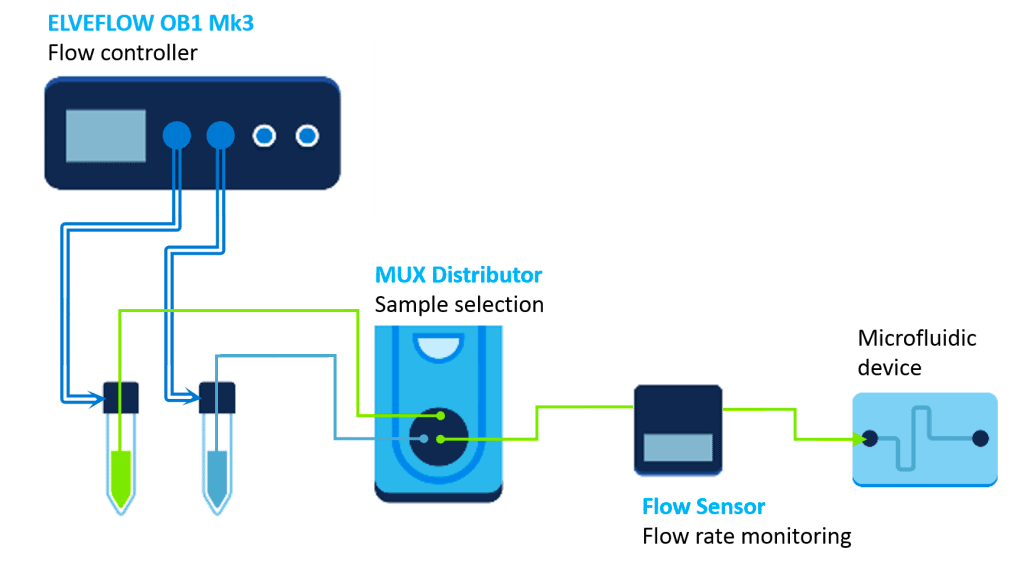

Setup diagram

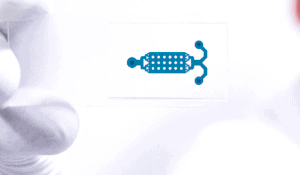

This following diagram and pictures shows the microfluidic setup used in this application note.

The reservoirs are connected to the OB1 Mk3, for the pressure control and also to the MUX distributor. The aim is to have all the liquids already plugged in to prevent any bubble during the experiment and obtain a fast medium switch.

The valve outlet is connected to the chip, this configuration allows to inject liquids sequentially. The use of a flow sensor is optional, but it allows to know in real time the injected volume for each liquid.

[ob1f_rebound]

You will find some pictures of the fluidic setup in the following gallery:

Protocol and results

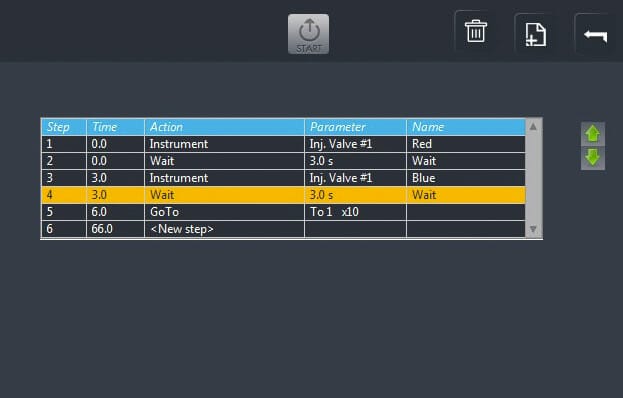

The MUX distributor enables the ability to have a simple control of the fast sample switch or medium switch. You enter your different solutions inside the software and ask for which one to inject inside the chip. The rotative valve will select your medium in less than one second. If a flow sensor is used in the setup, the software automatically displays the volume of injected liquid for each sample.

The fast sample switch can be done by hand but can also be automated thanks to the sequences programmer of the Elveflow software. This allows to obtain a better reproducibility and to plan long experiments. In the following video, a switch every 3 seconds between two liquids has been programmed. Note that no perturbation or air bubble have been introduced during the medium switches.

Advantages for flow chemistry:

- Excellent chemical compatibility with the wetted material

- No dead volume

- Compatible with all kind of microfluidic devices (micro mixers, micro reactors…)

- Large range of flow rate: from 70 nL/min to 5 mL/min

- Plug & Play and versatile system

- Automated experiments

- Also works for fraction collection

Microfluidics knowledge

Do you want tips on how to best set up your microfluidic experiment? Do you need inspiration or a different angle to take on your specific problem? Well, we probably have an application note just for you, feel free to check them out!

Job

Job Collaborations

Collaborations Customer

Customer Other

Other