Published on 27 August 2019

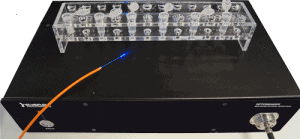

The OptoReader is a highly sensitive detection device taking advantage of advanced photo-detection technologies. Its optical fiber based design and its capacity of both excitation and detection of fluorescence makes it the ideal device for working with fiber optic sensors.

Fiber optic chemical sensors have important applications in challenging fields such as clinical diagnosis, pollution monitoring, oceanography, chemical process monitoring…

In this application note, we demonstrate the ability of the OptoReader to detect the change in fluorescence of a tiny amount of molecules adsorbed at the tip of an optical fiber.

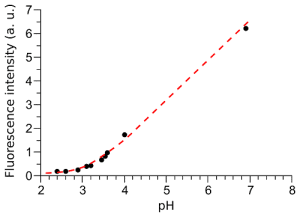

Based on the Fluorescein isothiocyanate (FITC)’s fluorescence efficiency dependence on pH, a simple fiber optic sensor of pH can be thus fabricated by adsorbing FITC molecules at the extremity of an optical fiber.

Efficient adsorption of FITC molecules to the extremity of a glass optical fiber can be achieved using FITC-labeled poly(L-lysine). The polylysine is attractive to negatively charged surface. On the other hand, glass surfaces immersed in water is known to acquire a negative surface charge density, primarily through the dissociation of terminal silanol groups. Glass optical fiber with stable FITC coating can be obtained by dipping the fiber into a solution of poly(L-lysine)-FITC (PLL-FITC) in water.

Materials and samples Fabrication of the fiber optic pH sensor

PLL-FITC solution

PLL-FITC is obtained from Sigma-Aldrich (P3069) and is diluted at the proportion of 50 µmol/l of into water.

Fiber optic sensor

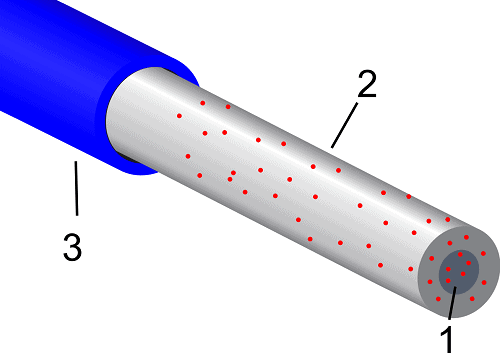

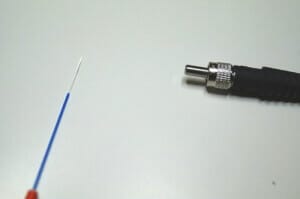

The fiber optic sensor is made from a step-index optical fiber. The wave-guiding effect is achieved by the difference of optical index between the core and the cladding. (See figure on the right for schematic structure of a step-index fiber). The core and cladding diameter used here are 400 µm and 425 µm, respectively and the numerical aperture is 0.5.

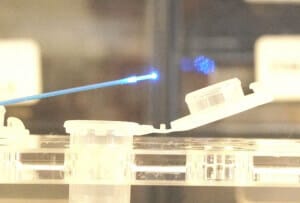

The sensor is prepared as follows:

- Remove the protection layers using cutting tools up to the plastic jacket protecting the glass optical fiber.

- Remove the plastic jacket at the extremity of the fiber using an appropriate un-stripping tool.

- Pre-charge negatively the fiber using corona discharge.

- Dip the fiber into the PLL-FITC solution for about 30 seconds and rinse with deionized water.

The solutions of different pH are obtained by diluting acetic acid into water containing 10 mmol/l of Hepes. The latter is a pH buffer which stabilizes the pH of the solution. The pH values are obtained using a commercial pH meter.

We use the OptoReader to measure the change in the fluorescence efficiency of the FITC molecules attached to the fiber sensor. The OptoReader offers high sensitivity detection and is designed to only use one optical fiber for both illumination and detection. These features make it ready for use with a fiber optic sensor.

The OptoReader runs on the Elveflow® Smart Interface, which offers smooth integration with other Elveflow® devices. SDK is also provided for simple interface with the popular programming languages (Matlab, Python, Labview, …).

- Fast acquisition

- High sensitivity

- Ambient light suppression by synchronous detection

- Simultaneous measurement of fluorescence and reflection

- Versatile integration

[starter_pack_rebound]

Measurement

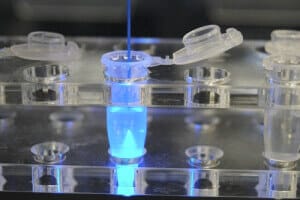

The OptoReader is capable of simutaneously excite and measure the fluorescence.

The pH measurement of a solution is done by dipping the FITC-coated optical fiber therein. Between the successive measurements, the fiber is rinsed in water containing pH buffer (Hepes 10 mmol/l). The OptoReader performs both excitation and detection of fluorescence and records the fluorescence change due to the effect of pH.

Conclusion

The OptoReader is a highly sensitive detection device taking advantage of latest photo-detection technologies and and fiber-based optics. Its capacity of simultaneous excitation and detection of fluorescence makes it a prominent candidate for working with fiber optic sensors.

Interested in fluorescent droplets monitoring? Check out our dedicated application note!

Microfluidics knowledge

Do you want tips on how to best set up your microfluidic experiment? Do you need inspiration or a different angle to take on your specific problem? Well, we probably have an application note just for you, feel free to check them out!

Job

Job Collaborations

Collaborations Customer

Customer Other

Other